Cups, Lids, and all things RFP

One of our reference companies in Catapult’s headquarters is on Starbucks. The world’s leader in brick-and-mortar coffee shops and an innovator of coffee culture. If you live in the Americas, Europe, or parts of Asia, you have likely seen or experienced Starbucks at least once. If you’ve placed an order, you probably used terms like Tall, Grande, or Venti to establish the size of your cup while Latte and Frappuccino were used to identify the ingredients of your hot or cold beverage. Of course, if you have been to Dunkin Donuts, you’ll also know how annoying it is to express the size of your drink since they don’t use those terms, but that’s a rant for another blog post.

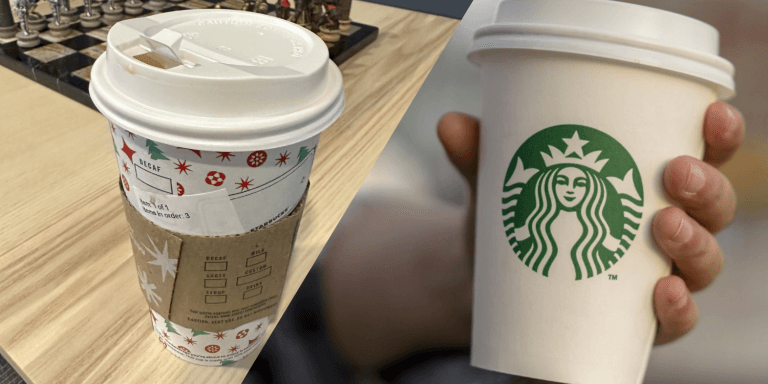

Old Version New Cup Size and Design

You may not know or even think about the operations behind the scenes. I am not referencing culture, politics, or how they make coffee. I’m referring to how the company operates. Think about every item that goes into running a Starbucks. Location, buildings, maintenance, coffee and espresso machines, cups, lids, stirring sticks, straws, aprons, and hardware.

Acquiring all of these things at a mass scale isn’t easy, even if you’re a small company. Much work goes into assessing the vendors who make or provide the goods and services that help curate the Starbucks experience. One advantage that Starbucks has is its sheer size. As the most significant coffee company in the world, Starbucks has almost all the negotiating power. They don’t need to buy one espresso machine for $6,800 USD; they need thousands. When they buy these devices in bulk, vendors take 30-40% off each machine in addition to throwing in heavily discounted maintenance and free parts. You want to talk about a DISCOUNT!!!

As they have grown and evolved, an essential procurement step for Starbucks is building out a centralized Request for Information and Proposal process to evaluate vendors’ capabilities (sellers) quickly. This helps Starbucks establish long-lasting partnerships and ensures that vendors understand timelines, pricing structures, and overall deliverables.

As I mentioned, we use the Starbucks use case at Catapult a lot, and this is a breakdown using Cups and Lids as an example.

Starbucks has 3 cup sizes, 12 oz, 16 oz, and 24 oz, each having different circumferences and heights. Recently, an RFP from Starbucks was used to pick a vendor that uses “Earth-friendly” materials without sacrificing the cup’s quality or the beverage’s taste. By outlining approved materials and the timeline for product creation and delivery, Starbucks successfully ordered and delivered billions of cups to locations around the world.

When the RFP was created, Starbucks provided supporting documents to each of the invited Vendors. The supporting documents included information on the amount of product they needed, the size they desired with CAD drawings, logos for placement and visibility, condensation requirements, and even the lid designs to ensure a snug and tight fit.

When Starbucks received everyone’s response, they brought in all of their crucial procurement stakeholders and a c-suite member to evaluate everyone’s response. During this process, they analyzed how answers were written, who delivered their answers on time, the pricing from each responding vendor, and references to validate that vendors can achieve the requirements.

The major downside to this latest RFP is the inability to account for the lid’s proper fit to the cup, as they had picked two different vendors to provide each of those products. As of January 15, 2023, there has been overwhelming chatter and news around Baristas (what would we do without them?) now becoming “lid testers” in each store to confirm the proper fit.

If you’re looking to execute a Request for Information/Proposal and want to take advantage of industry-leading templates, evaluation metrics, and public postings to receive bids, check out Catapult and see why thousands of people automate, standardize and accelerate the turnaround of better decision making.

You might also like

Why Proposal Response Software should mimic your firm’s internal Structure

Justin Witz ·May 17, 2022

Justin Witz ·May 17, 2022First pick of the NFL Draft chosen through RFP Process

Justin Witz ·May 2, 2022

Justin Witz ·May 2, 2022Why Responding to RFPs is like a Medieval Battle

Justin Witz ·April 22, 2022

Justin Witz ·April 22, 2022